I recently picked up a NOS replacement Finn 91/30 handguard and figured that it would make a good example for a tutorial in applying a pine tar finish. Let me preface this thread by stating that I am not sure whether or not that pine tar can be considered a correct finish, only that it provides the same appearance as the product that Finns originally used. The only documented Finnish stock finish that I am aware of is Kiväärintukkiöljy which is a dark stock oil comprised mainly of tung oil, varnish, and drying agents. The use of pine tar has been debated for decades. I have personally only encountered one Finnish rifle that had what looked (and smelled) to be copious amounts of wood pitch applied to stock. It was covered in preservative grease and included a hang tag so I doubt that it had been applied after import. All other rifles that I have encountered looked to have Kiväärintukkiöljy or another oil finish applied. Some of which had a stain applied prior to applying the oil finish. Many collectors will say that the use of pine tar is just a myth. I believe that the Finns used a few different stock finishes over the course of the Mosin Nagant's service life so it is difficult to say "never" based on the lack of documented evidence. The recipe was clearly altered several times based on the different appearances throughout and even within model designations. Look no further than a lot of the pre-war rifles which had much glossier finishes applied. The Finns were clearly using more varnish in their stock finish recipe during those times.

Hopefully this how-to will help someone come close to restoring the original appearance of a Finn stock that has been refinished here in the states.

Here's today's patient...hopefully the photos are acceptable. I chose to be lazy and used my cell phone instead of my Nikon.

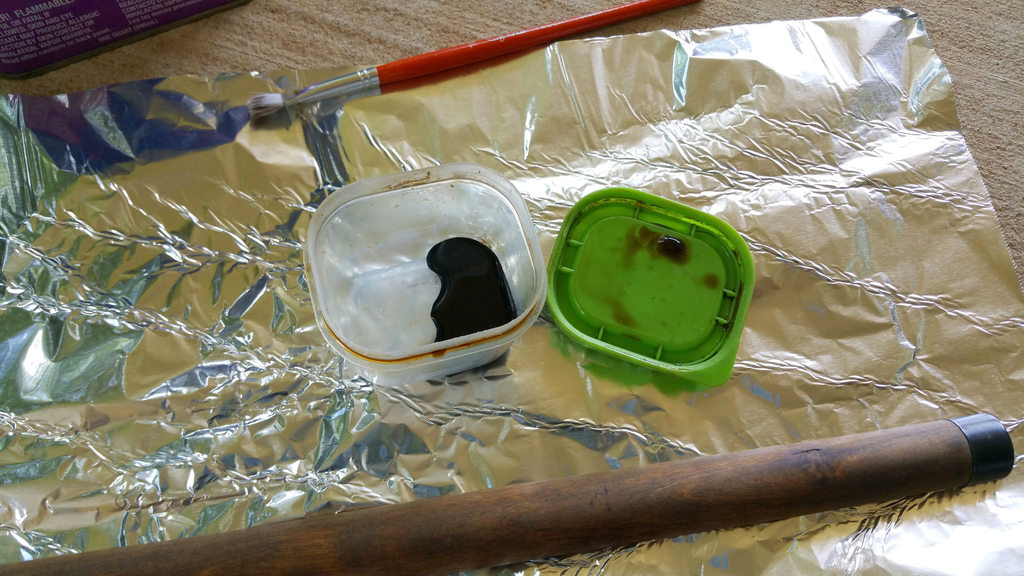

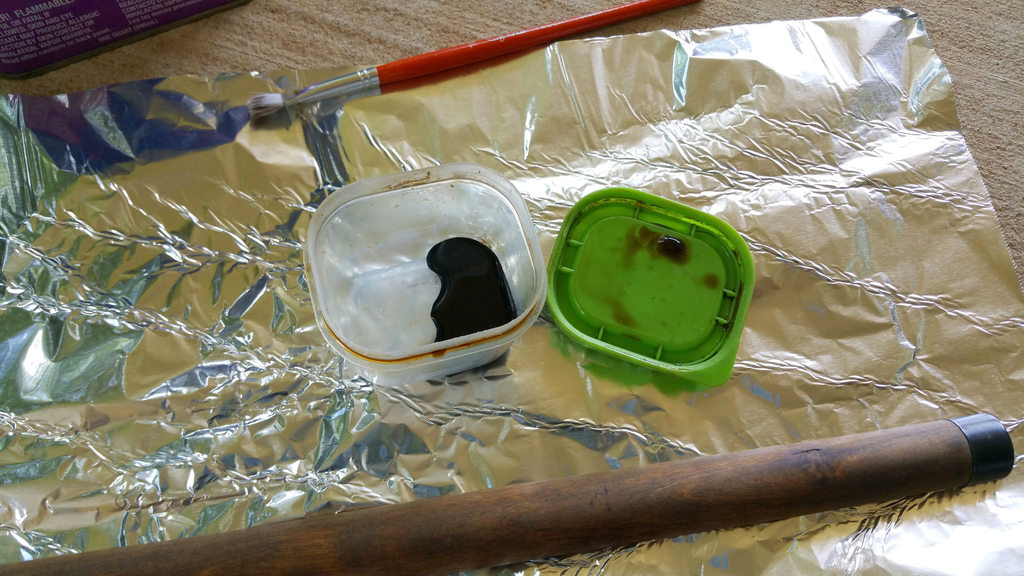

Materials needed: Pine tar (Auson Swedish Pine Tar works best) and pure turpentine. You'll also need a small container to mix the two ingredients in as well as a brush to apply it. Gloves will also come in handy too.

Mix a small amount of pine tar and turpentine...equal parts if you are wanting a drier, matte appearance similar to most M39's and post-war refurbs. If you are looking for a higher sheen you will need to apply straight pine tar and allow for it to fully cure, then scrub the hardened pine tar with a 3M non-scratch pad dipped in turpentine. This will remove the excess tar, scrub the finish into the wood, and burnish the surface as well. If you decide to apply straight pine tar it is usually a 2 week process to allow the tar to cure and then finish the scrubbing process. In my case, I mixed the pine tar at a 75/25 ratio with turpentine and did not allow the tar to harden.

After coating the wood, place it somewhere safe in the sun to bake. It helps drastically if the temps are at least 90 degrees. An alternate heat source (like a heat gun) will work, but it takes a ton of work.

After you have allowed the pine tar to sit on the wood for an extended period of time (this handguard sat in the sun for 8 hours), wipe (or scrub) down the wood with turpentine. You should see results similar to those in the photo below (no stains or oils have been applied...only pine tar and turpentine).

After allowing at least 48 hours to dry you may stain or apply oil if needed. I would recommend staining with an alcohol based stain after applying the pine tar if you are trying to match an existing piece of wood. If you stain first you will likely end up with darker wood that has little contrast in the figured areas. The handguard shown in the photos below has been lightly toned with RIT brown dye since the spliced forend on the rifle was slighly darker than the rest of the stock. It then received a coating of pure dark tung oil. After the previous coat has fully cured, I will likely add an additional coat of pine tar.

Hopefully this how-to will help someone come close to restoring the original appearance of a Finn stock that has been refinished here in the states.

Here's today's patient...hopefully the photos are acceptable. I chose to be lazy and used my cell phone instead of my Nikon.

Materials needed: Pine tar (Auson Swedish Pine Tar works best) and pure turpentine. You'll also need a small container to mix the two ingredients in as well as a brush to apply it. Gloves will also come in handy too.

Mix a small amount of pine tar and turpentine...equal parts if you are wanting a drier, matte appearance similar to most M39's and post-war refurbs. If you are looking for a higher sheen you will need to apply straight pine tar and allow for it to fully cure, then scrub the hardened pine tar with a 3M non-scratch pad dipped in turpentine. This will remove the excess tar, scrub the finish into the wood, and burnish the surface as well. If you decide to apply straight pine tar it is usually a 2 week process to allow the tar to cure and then finish the scrubbing process. In my case, I mixed the pine tar at a 75/25 ratio with turpentine and did not allow the tar to harden.

After coating the wood, place it somewhere safe in the sun to bake. It helps drastically if the temps are at least 90 degrees. An alternate heat source (like a heat gun) will work, but it takes a ton of work.

After you have allowed the pine tar to sit on the wood for an extended period of time (this handguard sat in the sun for 8 hours), wipe (or scrub) down the wood with turpentine. You should see results similar to those in the photo below (no stains or oils have been applied...only pine tar and turpentine).

After allowing at least 48 hours to dry you may stain or apply oil if needed. I would recommend staining with an alcohol based stain after applying the pine tar if you are trying to match an existing piece of wood. If you stain first you will likely end up with darker wood that has little contrast in the figured areas. The handguard shown in the photos below has been lightly toned with RIT brown dye since the spliced forend on the rifle was slighly darker than the rest of the stock. It then received a coating of pure dark tung oil. After the previous coat has fully cured, I will likely add an additional coat of pine tar.

Last edited: