Yeah, I suppose that makes sense. I'll have to look at it. I'll see how my Ed Brown was done. Maybe that will give me an idea.I think it's best to contour with the grip safety in the position it is in while you are gripping the frame. After all you want it to feel the best when you are shooting it. Same goes for contouring the thumb safety which you should do along with contouring the grip safety.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I used the same jig for my beavertail. Worked great, just take your time and the results will speak for themselves.

I think your plan to reprofiled factory grips will really make that frame feel comfortable in your hands.

This is the most interesting post this site has had in many years.

Thank you.

Super! Very interesting and admirable on your part to undertake a task like this. I largely agree with robar-g19 here; this is an excellent post and we need more like it! Keep up the work and be sure to keep us updated on your progress. I'm diggin' it!

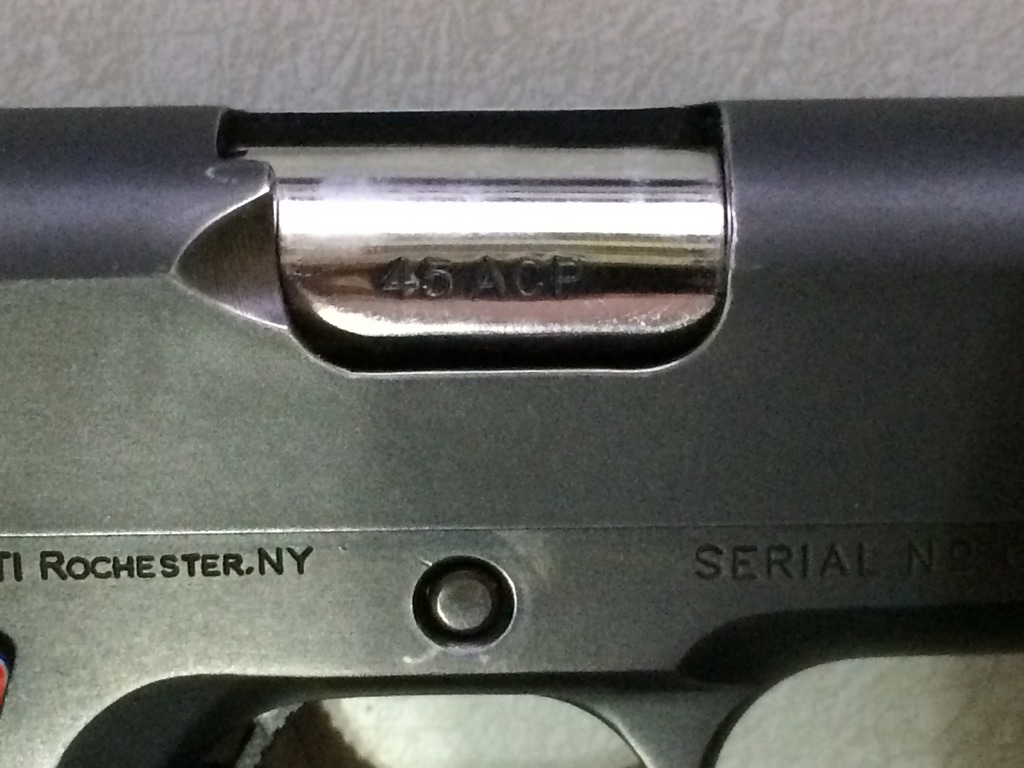

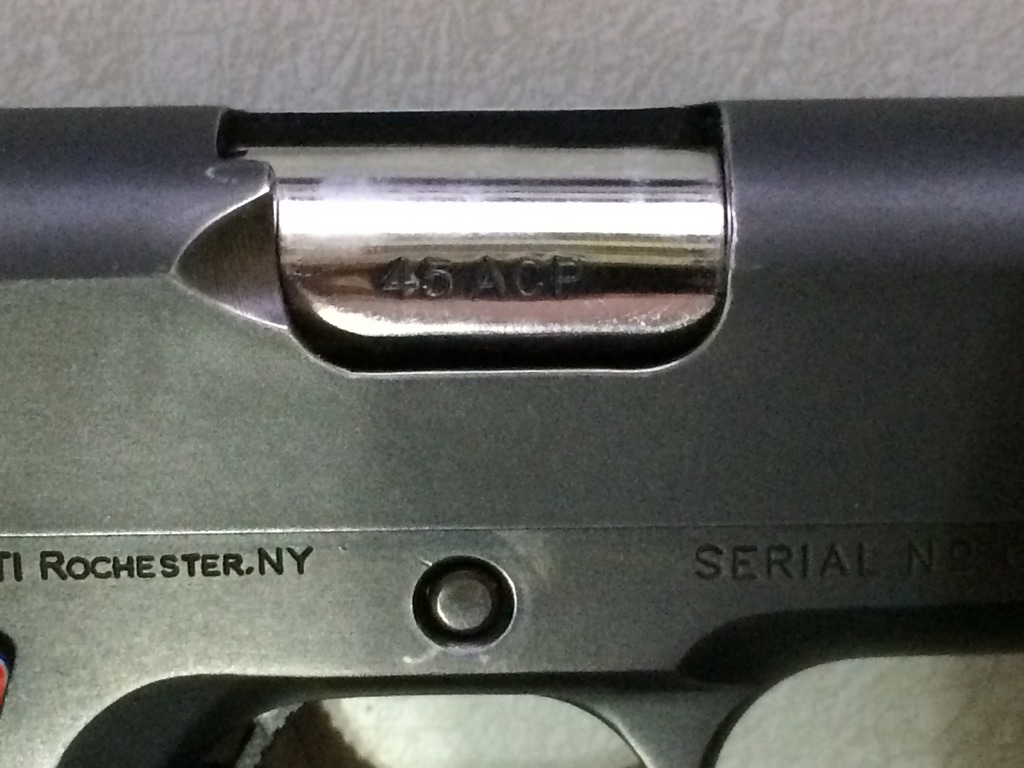

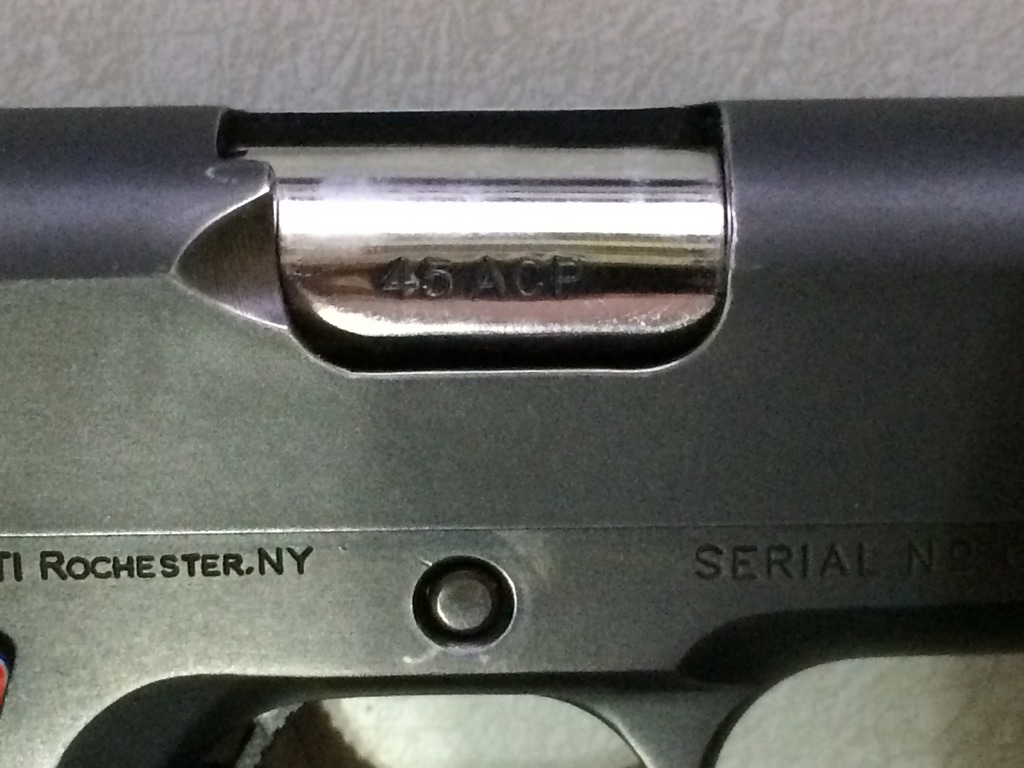

Very good thread and I'm glad to see someone else doing this! I started on "Project ATI Commander Bobtail" over a year ago. Unfortunately work took a turn for the very busy and I haven't completed it yet. I started with an ATI "American Tactical M1911 GI-E, that I got on sale for around $320 delivered. Here's what I've done so far:

- Ed Brown bobtail MSH (using the same EB jig)

- heavily contoured it to the frame (they come "proud" of the frame)

- heavily beveled magwell

- undercut trigger guard

- lowered and flared the ejection port (the ATI came with the original Colt pattern, unbeveled or relieved port)

- beveled the flat cut hole in the Commander hammer

- flush cut slide stop

- installed a fiber optic rod in the stock front sight

- "U" bottomed and widened the back sight notch, for quicker sight acquisition

- replaced the ejector with an extended Wilson ejector

- installed Wilson bulletproof slide stop and Wilson bulletproof thin, single side thumb safety

- upgraded to a Wolff extra power 22#recoil spring and extra power firing pin spring, and a Nowlin competition sear spring

- fitted an EGW thick flange, angle bore bushing with carry bevel, along with a long nose recoil spring plug to match

- fitted an EGW flat bottom firing pin stop

- installed an STI short polymer trigger, adjustable for takeup and overtravel

- polished the disconnector

- trigger job set to a crisp 4.5#, with neutral sear engagement, properly set takeup to ensure the half cock notch works correctly and overtravel properly set to prevent interference with the sear as the hammer falls

- adjusted the grip safety engagement to ensure positive function

- some internal polishing on rough spots and high points to increase overall smoothness

- Installed short grip screw bushings and a set of thin VZ Operator II's I picked up used for $40 and bobtailed to match the frame (also had to "defang" the Op II's for CCW, still grippy but not painful!)

- Wilson 47D 8 round mags with low profile pads

- full carry bevel

- 45 degree flush cut barrel crown

- stipple or checker the front strap and MSH "CCW style" which means not all the way to the sides of the frame, for greater comfort (this may be the only mod I farm out, as I'm too chicken to do it)

- Trijicon HD or Ameriglo Pro front sight

- full refinish (still undecided on color, either two tone Cerakote or satin hard chrome frame and ion-bond slide)

I like the way the grips and frame are matched.

Very good thread and I'm glad to see someone else doing this! I started on "Project ATI Commander Bobtail" over a year ago. Unfortunately work took a turn for the very busy and I haven't completed it yet. I started with an ATI "American Tactical M1911 GI-E, that I got on sale for around $320 delivered. Here's what I've done so far:

I think it's going well so far. Comments?

Looks like I've got some competition. Looks pretty darn good to me. I'll be interested to know what route you take to finish it when you're done. I'm leaning towards cerakote.

Very good thread and I'm glad to see someone else doing this! I started on "Project ATI Commander Bobtail" over a year ago. Unfortunately work took a turn for the very busy and I haven't completed it yet. I started with an ATI "American Tactical M1911 GI-E, that I got on sale for around $320 delivered. Here's what I've done so far:

Still left to do:

- Ed Brown bobtail MSH (using the same EB jig)

- heavily contoured it to the frame (they come "proud" of the frame)

- heavily beveled magwell

- undercut trigger guard

- lowered and flared the ejection port (the ATI came with the original Colt pattern, unbeveled or relieved port)

- beveled the flat cut hole in the Commander hammer

- flush cut slide stop

- installed a fiber optic rod in the stock front sight

- "U" bottomed and widened the back sight notch, for quicker sight acquisition

- replaced the ejector with an extended Wilson ejector

- installed Wilson bulletproof slide stop and Wilson bulletproof thin, single side thumb safety

- upgraded to a Wolff extra power 22#recoil spring and extra power firing pin spring, and a Nowlin competition sear spring

- fitted an EGW thick flange, angle bore bushing with carry bevel, along with a long nose recoil spring plug to match

- fitted an EGW flat bottom firing pin stop

- installed an STI short polymer trigger, adjustable for takeup and overtravel

- polished the disconnector

- trigger job set to a crisp 4.5#, with neutral sear engagement, properly set takeup to ensure the half cock notch works correctly and overtravel properly set to prevent interference with the sear as the hammer falls

- adjusted the grip safety engagement to ensure positive function

- some internal polishing on rough spots and high points to increase overall smoothness

- Installed short grip screw bushings and a set of thin VZ Operator II's I picked up used for $40 and bobtailed to match the frame (also had to "defang" the Op II's for CCW, still grippy but not painful!)

- Wilson 47D 8 round mags with low profile pads

It feels like a completely different gun than it did out of the box. It no longer slings brass 20 feet, as it was seriously undersprung in stock form. It feels better, handles better, operated more smoothly and is more accurate. The barrel link was very well fit out of the box, but the stock bushing fit was terrible. Everything was pretty much done by hand, including blending the MSH to the frame with files, sandpaper and polish. I think it's going well so far. Comments?

- full carry bevel

- 45 degree flush cut barrel crown

- stipple or checker the front strap and MSH "CCW style" which means not all the way to the sides of the frame, for greater comfort (this may be the only mod I farm out, as I'm too chicken to do it)

- Trijicon HD or Ameriglo Pro front sight

- full refinish (still undecided on color, either two tone Cerakote or satin hard chrome frame and ion-bond slide)

Nice work!

Similar threads

- Replies

- 141

- Views

- 19K

- Replies

- 32

- Views

- 2K

- Locked

- Replies

- 22

- Views

- 2K

Join the conversation!

Join today and get all the highlights of this community direct to your inbox. It's FREE!

- Curated content sent daily, so you get what's interesting to you!

- No ads, no large blocks of text, just highlights for easy digest

- It's all totally free!

Enter your email address to join:

Thank you for joining!

Already

a member? Click here to log in