You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I am game for this. Not everyday you get to do this!

I'd be interested as well...

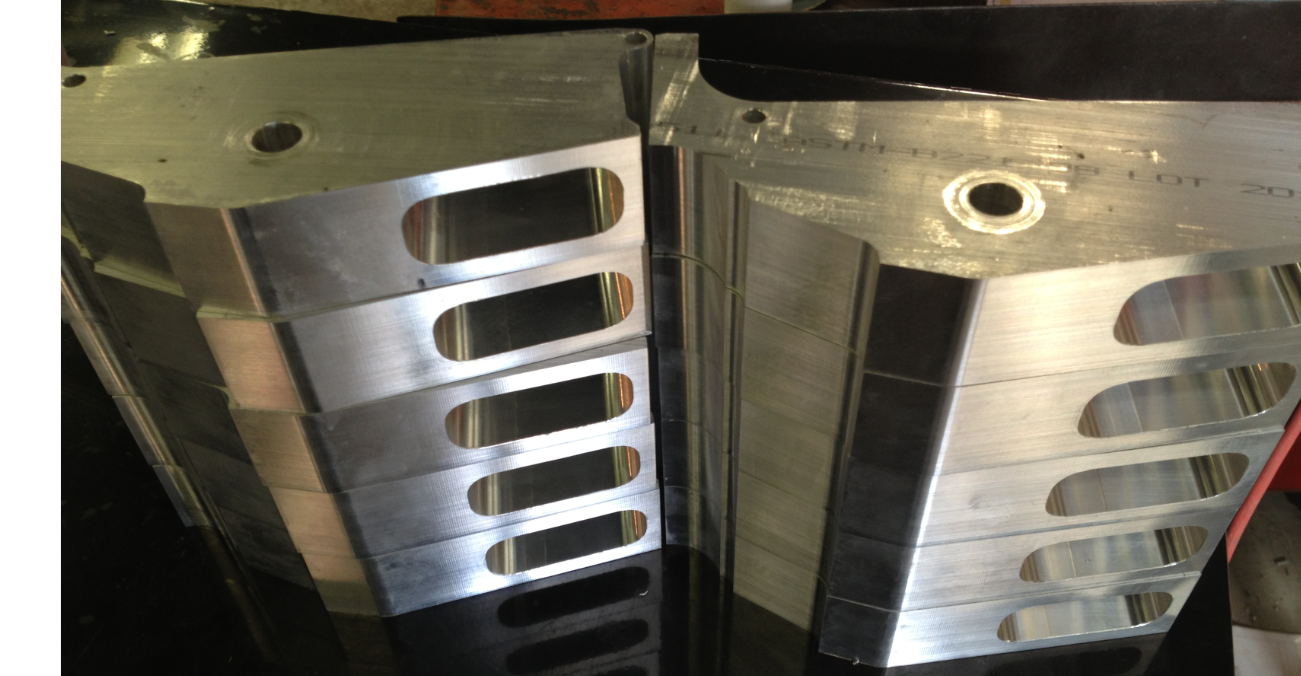

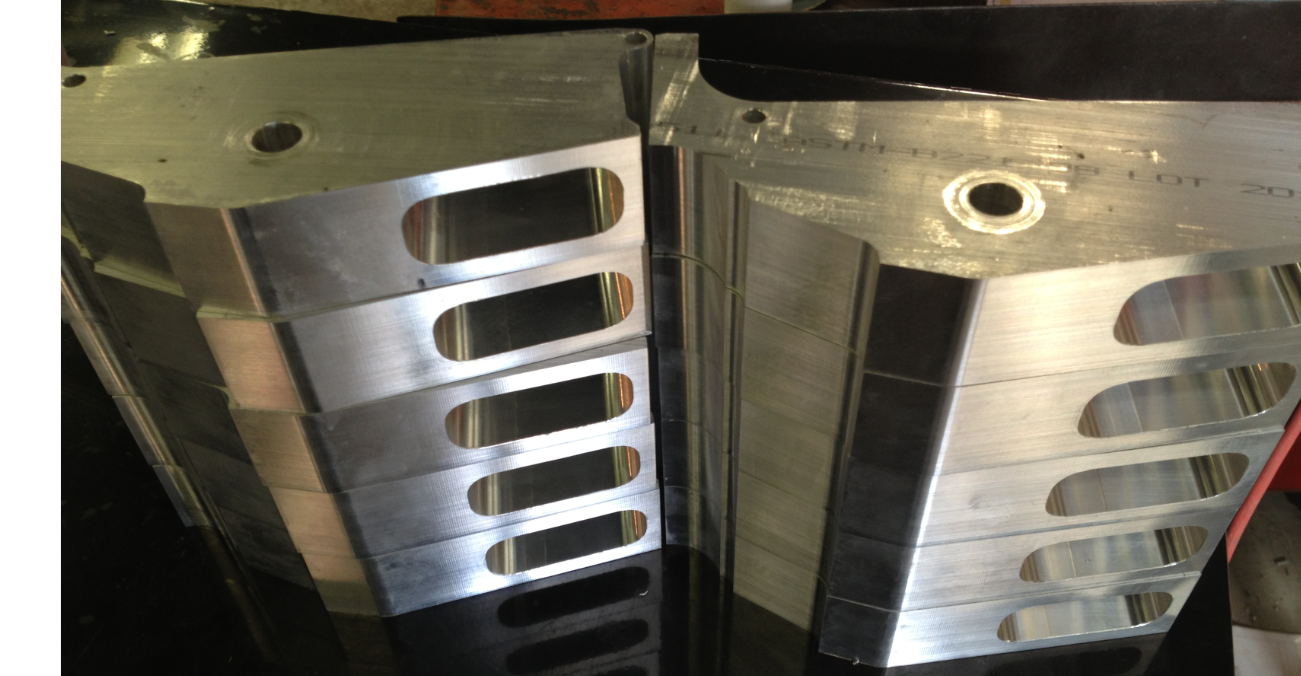

First 10 test lowers are off to be broached. I've just placed an order for enough barstock to make 200 more and it will be here next week.

The magwells are perfectly cut with no tool marks or blend lines. I opted for much more expensive tooling to enable cutting from one side instead of flipping the part, resulting in a perfect finish on the sidewalls.

The lines you see running down the walls are reflections, not tool marks.

The magwells are perfectly cut with no tool marks or blend lines. I opted for much more expensive tooling to enable cutting from one side instead of flipping the part, resulting in a perfect finish on the sidewalls.

The lines you see running down the walls are reflections, not tool marks.

Lookin good! Ever since I saw the webistes on the guys that are printing working lowers I've been interested in "making" my own...

Out of curiosity, did you write your own CAD for these, or are you using one of the variations available online (such as the BiggerHammer plans)? Just curious. Options such as a Seekins Precision type finger guard would be awesome, but not sure how feasible from the machining side...

Out of curiosity, did you write your own CAD for these, or are you using one of the variations available online (such as the BiggerHammer plans)? Just curious. Options such as a Seekins Precision type finger guard would be awesome, but not sure how feasible from the machining side...

The model used was meticulously created from mil-spec and then customized to set it apart aesthetically and increase functionality in certain areas.

I just purchased a $40,000 6 axis probe for inspection and reverse engineering to ensure we maintain top quality inspection throughout the manufacturing process.

I'll post pics once it arrives.

I just purchased a $40,000 6 axis probe for inspection and reverse engineering to ensure we maintain top quality inspection throughout the manufacturing process.

I'll post pics once it arrives.

The model used was meticulously created from mil-spec and then customized to set it apart aesthetically and increase functionality in certain areas.

I just purchased a $40,000 6 axis probe for inspection and reverse engineering to ensure we maintain top quality inspection throughout the manufacturing process.

I'll post pics once it arrives.

what are the material specs for the billet lowers?

what are the material specs for the billet lowers?

They are being made from 7075-T6 aluminum and mill certs will be made available should you want them.

The model used was meticulously created from mil-spec and then customized to set it apart aesthetically and increase functionality in certain areas.

I just purchased a $40,000 6 axis probe for inspection and reverse engineering to ensure we maintain top quality inspection throughout the manufacturing process.

I'll post pics once it arrives.

I'm glad to hear you're doing it right!

I'm terrified that these things are going to cost $500 a piece and that would suck because this is such a great idea and I'd really like to get 2 or 3.

If somebody is keeping a list of some kind please make sure my name is on it!

If somebody is keeping a list of some kind please make sure my name is on it!

Similar threads

- Replies

- 0

- Views

- 101

- Replies

- 18

- Views

- 2K

- Replies

- 4

- Views

- 174

Join the conversation!

Join today and get all the highlights of this community direct to your inbox. It's FREE!

- Curated content sent daily, so you get what's interesting to you!

- No ads, no large blocks of text, just highlights for easy digest

- It's all totally free!

Enter your email address to join:

Thank you for joining!

Already

a member? Click here to log in