Ever considered slatwall?? Available at Menards, etc and retail store displys outlets. Retail stores use them extensively for flexible display options. It is 3/4" thick 4'x8' sheets MDF with grooves 3" on center. Can add groove liners for visuals and stronger load rating. My son is moving into new home after Jan 2 featuring a large dedicated shop. I'm contributing a full slatwall lining for organization and visuals. Have used slatwall in many installations....shops, walk-in gun vaults, garages, hobby rooms. Looks great and very functional.So, when my parents came out to OK for Thanksgiving they had a great time. My dad is older, 82, but still very active and capable/stong and always wants a project to do. Unfortunately there is far less to do around our property in the winter than spring/summer. Plus I wanted them to just relax and enjoy since it was their first trip to OK since my wife and I got married in 1999. On their trip my dad mostly fiddled around in my 30x40 shop organizing things from our move to the property. It was mostly helpful. He kept asking for a project to do and had to steer him in different directions as I wasn't ready for big projects.

My shop is 30x40 red iron with the vinyl backed insulation. The walls have horizontal red iron supports that ring the structure at 8' off the floor. My biggest future project to help organize the shop is to install 3/4" o 23/32" plywood all along the first 96" of the shop. THis allows me to have much more utility in my shop with building heavy duty work benches, shelving units and storage racks for tools like rakes, shovels, sledges and any other tools with long handles. THe plywood gives me a good base to screw things into with better support.

My folks are coming back out in the spring to visit again and they both are begging to have a project ready for my dad to help work on. So, for Christmas my parents got me two gift cards to home depot for plywood. It's a lot of money on the cards so this is the start/planning stage for "the

big project". So, here is the big question after typing all this.

I'll be using the 3/4" range plywood. Nothing with sanded finish but a good structural panel that is moisture resistant. When I install these vertically side by side I'll be using hex self tapping screws to go into the red iron. Do i need to use a visqueen plastic moisture barrier in between the plywood and the vinyl backed fiberglass insulation? I will eventually put a wood stove in the shop and don't currently have an A/C unit but that is down the line too. Is this necessary to do when there is not a current problem with moisture in a shop environment? there will be an air gap of about 2" between the insulation and the back of the plywood. If it matters, I'll be holding the bottom edge of the plywood off the concrete floor by about 1/4" and will be painting the interior facing sheets of plywood with white paint. Filling any knot holes/divets with bondo prior to painting.

Let me know your thoughts on the plastic vapor barrier and whether needed or not. if you did something different but with a similar outcome let me know what you did. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I would just use them as a backer on the seams of the plywood not necessarily attached to the red iron or floor at all. Just a brace to keep the seams together. The 3/4 ply would be enough structure unless you are really using the wall for something heavy. Regular sheetrock screws or self drillers would work fine. I you wanted, you could back them with flat fender washers to prevent tear-out. Just a suggestion.Would you tack weld those in or cut them long and shot-pin or screw them in. Wheeler Metals has the 1.5"x3" red iron for $1.77/foot. A little more expensive but may take more time with the lighter gauge steel to fab to fit rather than just cutting and a couple beads of weld on the 14ga stuff. How would you install the above if you used them?

If you wanted to fasten them to the floor just use Remington or Hilti 22 cal ramset. Cut the stud on a 90 and bend it then WHAM! to the concrete.

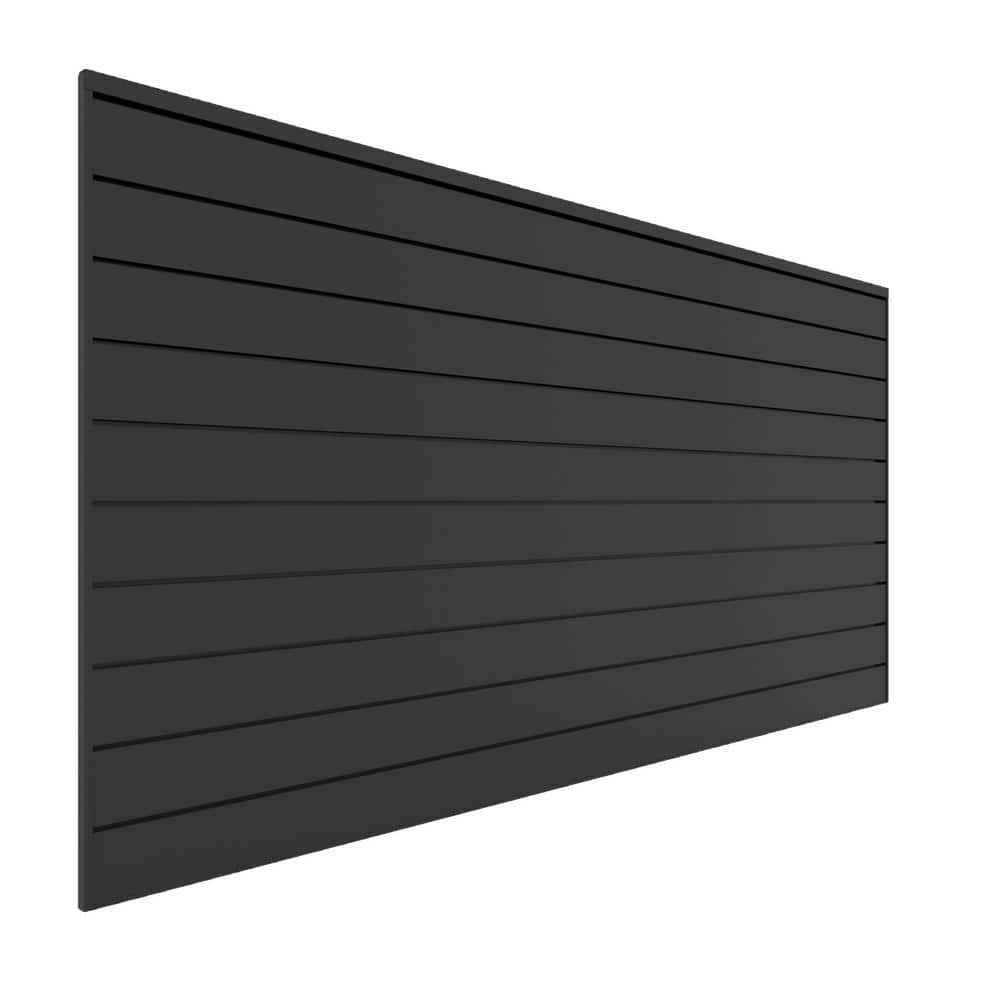

Ever considered slatwall?? Available at Menards, etc and retail store displys outlets. Retail stores use them extensively for flexible display options. It is 3/4" thick 4'x8' sheets MDF with grooves 3" on center. Can add groove liners for visuals and stronger load rating. My son is moving into new home after Jan 2 featuring a large dedicated shop. I'm contributing a full slatwall lining for organization and visuals. Have used slatwall in many installations....shops, walk-in gun vaults, garages, hobby rooms. Looks great and very functional.

I don't think there is a Menards anywhere in Oklahoma. We were looking for slatwall a while back and couldn't find any at Lowes or Home Depot.

I may have used a 1/4" gap, cant remember but I never saw the concrete floor sweat. It possible though.

The concrete floor in my shop sweats horribly in weather like this. I have to keep a pair of large ceiling fans running to keep the ferrous tools from rusting.

I like this idea and May suggest corrugated tin for it. If looks good and is easy to useIf you have room and do any welding/grinding/cutting torch work. May I suggest using metal on the walls where you do such at. Make a dedicated area for such work. I lined all my shops I built with seconds/blemish metal panels. But a guy could just install it on a dedicated area.

Use self tapping screws for screwing metal studs together (if structural), non self tapping sheet metal screws if non structural, not drywall screws. You use drywall screws to screw drywall to themAll the metal studs I've ever seen were screwed in place, usually with 1/4" long drywall screws.

Looks like Home Depot has it available for shipping to store for pickup.I don't think there is a Menards anywhere in Oklahoma. We were looking for slatwall a while back and couldn't find any at Lowes or Home Depot.

Proslat PVC Slatwall 8 ft. x 4 ft. Charcoal 88105 - The Home Depot

Proslat Slatwall Panels are built Strong - Panels can hold up to 75 lb. per sq.ft and are Guaranteed for life. Durable - Unlike wood slatwall, our high density PVC slatwall is resistant to moisture. Versatile

www.homedepot.com

i ut osb in my shop and painted it.works great

Wichita is the closest I've found.I don't think there is a Menards anywhere in Oklahoma. We were looking for slatwall a while back and couldn't find any at Lowes or Home Depot.

Wichita is the closest I've found.

Wife tells me that the slatboard can be ordered either through one of the big box stores or through Amazon. As for the big box stores, it would have to be ordered and delivered to that store.

Similar threads

Join the conversation!

Join today and get all the highlights of this community direct to your inbox. It's FREE!

- Curated content sent daily, so you get what's interesting to you!

- No ads, no large blocks of text, just highlights for easy digest

- It's all totally free!

Enter your email address to join:

Thank you for joining!

Already

a member? Click here to log in