Deciphering Belgian Proof Marks

A reader has asked me to say something about Belgian proof marks. I've owned two Belgian side by sides and two Browning Superposed, so I gu...

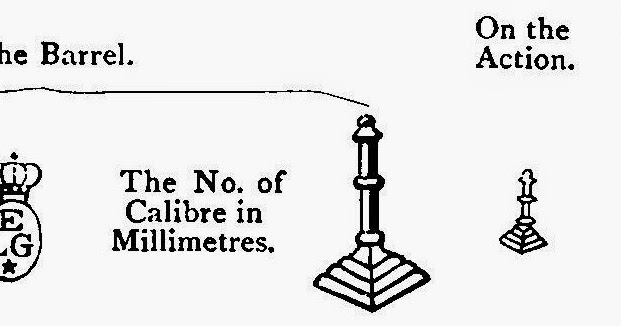

gives you a little insight into Belgian guns. might help with others as you figure out how the marks "read".